Concrete piles play a crucial role in construction, especially in a state like Florida where the soil and environmental conditions require specific engineering solutions. In this article, we’ll dive into the world of Florida DOT precast concrete piles. We’ll break it down into easy-to-understand sections so that even a young child could grasp the basics.

What Are Concrete Piles?

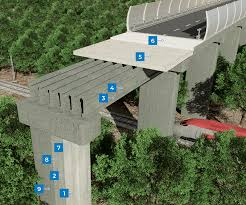

Concrete piles are long, sturdy columns made from concrete. They are buried deep into the ground to support buildings, bridges, and other structures. Imagine them as giant straws that hold up the big drinks (or buildings) we see around us. When you build something heavy, like a tall building, the ground alone might not be strong enough to hold it up. That’s where these piles come in. They help transfer the weight of the building from the top down to the stronger, deeper layers of soil or rock.

Why Are Concrete Piles Important in Florida?

Florida has unique soil conditions that make concrete piles especially important. The soil in many parts of Florida can be soft and unstable. If a heavy building was just placed on this type of soil, it could sink or lean over time. Precast concrete piles help solve this problem by going deep into the ground, past the soft layers, to reach stronger soil or rock that can support the structure. This way, the building or bridge remains stable and safe.

What Does “Precast” Mean?

You might have heard the word “precast” before, but what does it really mean? Precast concrete piles are made in a factory before they are ever used on a construction site. Think of it like baking cookies: you make the dough (or concrete) in advance, then put them in the oven (or curing area) to set. When they are done, you take them out and use them wherever they are needed. This method ensures that the piles are made with the same quality every time, making them reliable and strong.

The Role of the Florida Department of Transportation (DOT)

The Florida Department of Transportation (DOT) is responsible for making sure that roads, bridges, and other transportation-related structures are built safely and efficiently. When it comes to precast concrete piles, the DOT sets standards and guidelines to ensure they meet the necessary safety and performance requirements. This helps to make sure that the piles can handle the weight and stress they will encounter once they are put into use. Aslo read Florida Atlantic vs Charlotte: A College Football Showdown

How Are Florida DOT Precast Concrete Piles Made?

Making precast concrete piles involves several steps. First, the concrete mixture is prepared. This mixture usually contains cement, sand, gravel, and water. It is carefully measured and mixed to ensure that the final product is strong and durable. Next, the concrete is poured into molds that shape the piles. These molds give the piles their long, cylindrical shape.

Once the concrete is in the molds, it is allowed to cure. Curing is like letting the dough rise before baking. The concrete needs time to harden and gain strength. This can take several days. After curing, the piles are removed from the molds and inspected to make sure they meet the quality standards. Finally, they are transported to the construction site where they will be used.

Benefits of Using Precast Concrete Piles in Florida

Precast concrete piles offer several benefits, especially in Florida. First, they are very strong and durable. This makes them ideal for supporting heavy structures, even in challenging soil conditions. Second, because they are made in a factory, their quality is consistent and reliable. This means fewer surprises during construction. Third, precast piles can be installed quickly. This speeds up the construction process and reduces delays.

Installation of Precast Concrete Piles

The installation of precast concrete piles involves a few key steps. First, a hole is dug in the ground where the pile will be placed. This is often done using specialized equipment like augers or drills. Once the hole is ready, the precast pile is lowered into place. This is usually done with a crane.

After the pile is in position, it needs to be driven into the ground. This is done using a pile driver, which is a machine that uses heavy weights to pound the pile down into the soil. The pile is driven until it reaches the desired depth and is securely anchored in place. Finally, the pile is connected to the rest of the structure, providing the necessary support.

How Florida DOT Ensures Quality

The Florida DOT has strict guidelines and quality control measures to ensure that precast concrete piles meet high standards. They conduct regular inspections and tests to check the strength and durability of the piles. This includes checking the concrete mixture, examining the piles for any defects, and testing them under load conditions to make sure they perform as expected. These measures help to ensure that the piles will provide reliable support for the structures they are used in.

Challenges in Using Precast Concrete Piles

While precast concrete piles are very useful, there are some challenges associated with their use. One challenge is that the production of these piles requires precise control over the concrete mixture and curing process. If the mixture is not right, or if the piles do not cure properly, they might not be strong enough. Another challenge is transporting the piles to the construction site. They are heavy and can be difficult to move, especially in tight or busy areas.

Additionally, the installation of precast piles requires careful handling and precise equipment. If the piles are not installed correctly, they might not provide the necessary support. This is why it is important to work with experienced contractors who understand the requirements and challenges of using precast concrete piles.

Future Trends in Precast Concrete Piles

The field of precast concrete piles is always evolving. Advances in technology and materials are leading to new developments and improvements. For example, researchers are exploring new types of concrete mixtures that could make piles even stronger and more durable. There are also new construction techniques being developed that could make the installation of piles faster and more efficient.

In addition, there is a growing focus on sustainability. The concrete industry is looking for ways to reduce its environmental impact by using recycled materials and more energy-efficient production methods. These trends could lead to even better and more eco-friendly precast concrete piles in the future.

Conclusion

In summary, Florida DOT precast concrete piles are a vital part of construction in Florida. They provide strong and reliable support for buildings and infrastructure, especially in areas with challenging soil conditions. By being made in a factory and following strict quality standards, these piles ensure that construction projects are safe and durable.

Understanding the basics of precast concrete piles helps us appreciate the role they play in building the structures we rely on every day. From their manufacturing process to their installation and the challenges involved, knowing about these piles gives us insight into the careful planning and engineering that goes into creating safe and stable buildings and bridges.

As technology and methods continue to advance, the future of precast concrete piles looks promising, with improvements in strength, efficiency, and sustainability on the horizon. Whether you are a construction professional or just curious about how things are built, learning about Florida DOT precast concrete piles offers a glimpse into the world of engineering and construction.

If you ever see a new building or bridge going up, you might now think about the sturdy concrete piles hidden beneath the surface, quietly doing their job to support and stabilize the structure above.